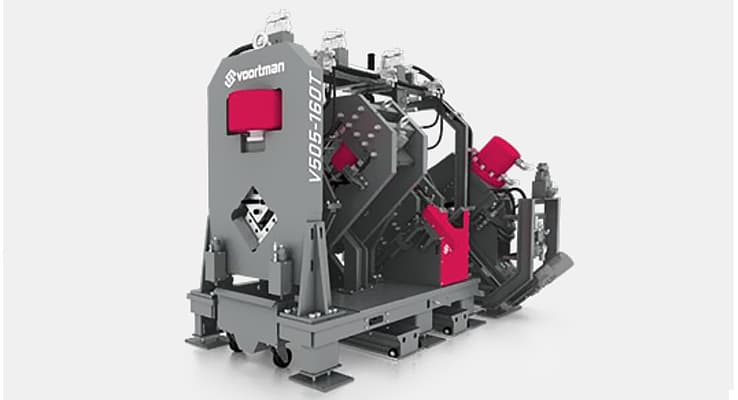

Beam Layout Welding Needle

The Beam Layout Welding features an Electrical Control Panel that provides maximum system control flexibility. The Welder is capable of operating in either manual or automatic modes. You can set the sequence of operation using the individual controls on your control panel. The welding parameters can be set on each head controller individually.